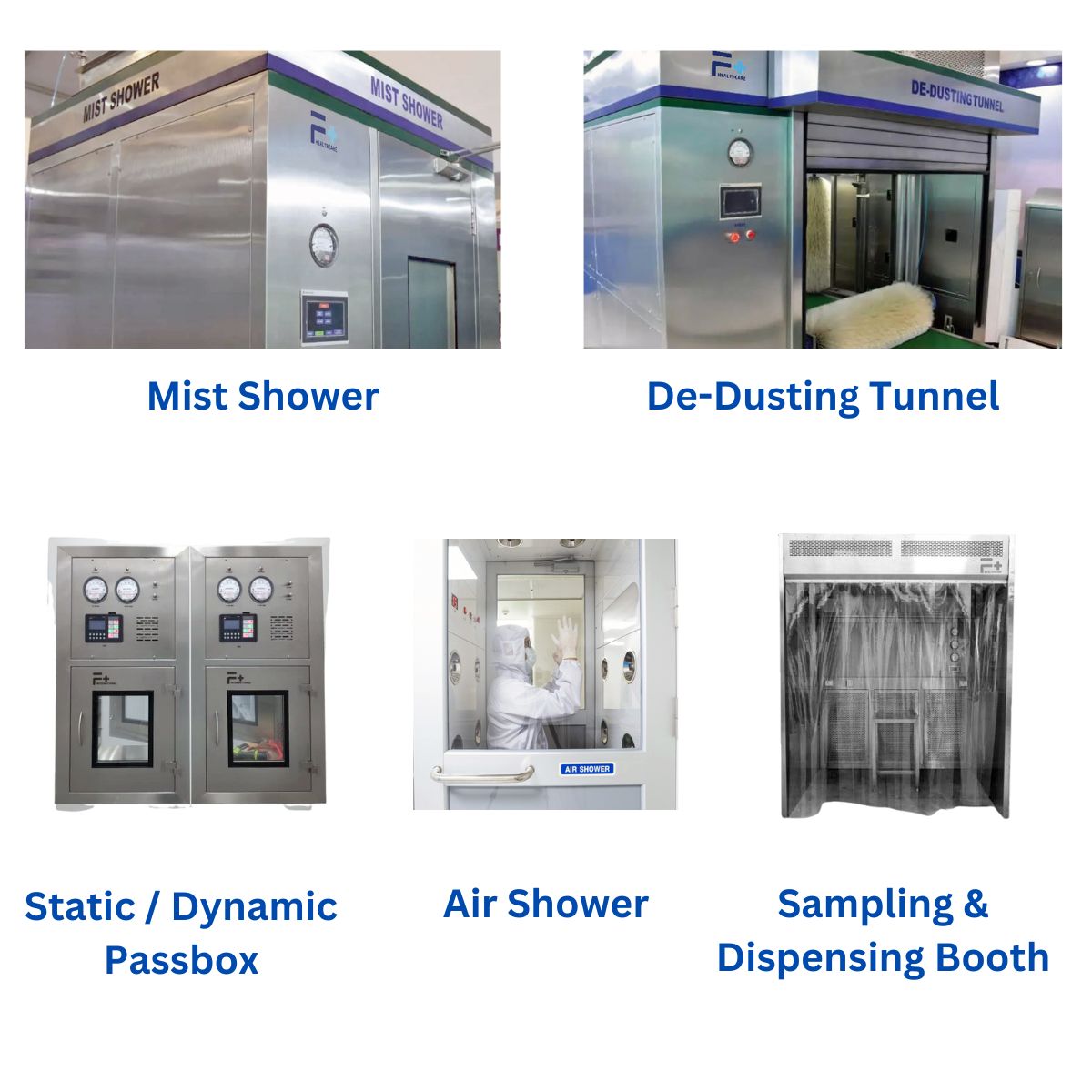

CLEANROOM EQUIPMENT

- Custom Design as per requirement

- MOC in SS 304/ SS 316

- PLC based control system

- Customizable as per the requirement

- Different Type of Equipment available like Static & Dynamic Passboxes, De-Dusting Tunnel, Air Shower, Mist Shower, Sampling & Dispensing Booth, Sampling & Weighing Booth etc.

- Certification & Compliance: GAMP5, CE, ATEX, cGMP compliant