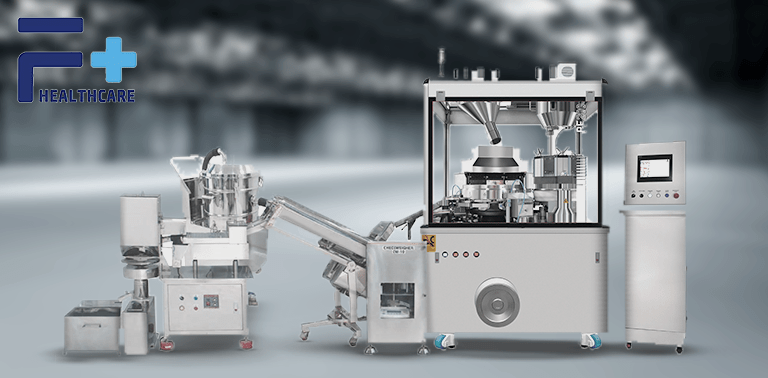

Peripheral Equipment for Automatic Capsule Fillers Machine

Take Your Capsule Filling Game to the Next Level with These Must-Have Peripherals

Capsule filling machines have become a popular choice for manufacturers looking to streamline their capsule production processes. However, to maximise the efficiency and output of these machines, it’s essential to pair them with the right peripherals. In this article, we explore some of the top peripheral equipment that can be attached to a capsule filling machine to optimise its performance and output. These peripherals are made of pharma grade approved SS 316L & SS 304. It can handle a wide range of capsules, ranging from Size 000 to 5. These peripheral equipment for automatic capsule fillers are capable of handling different type of capsules like Hard Gelatin, HPMC etc.

The Different Types of Peripheral Equipment for Automatic Capsule Fillers

1) Empty Capsule Sorter Elevator (ECSE):

An empty capsule sorter elevator is an ideal peripheral equipment for sorting empty capsules before they are fed into the capsule filling machine. The capsules are stored in the hopper & when the level of capsules in the capsule filling machine’s hopper falls below the pre-determined level, the ECSE starts loading the hopper of machine with the help of Air stream generated by the Air Blower mounted on the base structure. The capacity of this equipment ranges from 100,000 to 200,000 capsules/hour.

2) Capsule Polisher (DPM):

The Capsule Polisher uses the rotating brush concept to clean the capsules on a continuous basis. Capsules are fed into a cylindrical chamber (polishing chamber) where a rotating spiral brush removes the powder particles sticking to the outer surface of capsules and, at the same time, transports the capsules forward. A vacuum cleaner, better known as a capsule de-duster – the suction side of which is used for cleaning purposes – is to be used to suck the de-dusted particles on a continuous basis. The continuous rubbing of capsules against the rotating brush ensures complete polishing of the capsules. The capacity of this equipment ranges from 100,000 to 200,000 capsules/hour.

3) Filled Capsule Sorter (FCS):

The FCS consists of a drum sorter with sorting plates of a specific size & configuration. The geometry of the holes is designed in such a manner that capsules which are diametrically defective or oversized (which can affect the later process such packaging) get sorted. The defective capsules gets trapped in the sorting plate of the drum sorter while good capsules pass through. The trapped capsules can be removed manually at regular intervals. The capacity of this equipment ranges from 100,000 to 200,000 capsules/hour

4) Mini Capsule Sorter (MCS):

A mini capsule sorter is a compact peripheral equipment mounted on an electromagnetic vibratory motor which imparts a vibratory motion. The sorting section is designed in such a manner that the loose caps coming along with the filler capsules fall through the holes in the sorting plate as the capsule move forward along the plate. The capacity of this equipment ranges from 100,000 to 200,000 capsules/hour.

5) Filled Capsule Elevator:

The machine works on the principle of air lifting of filled capsules to lift the capsules from a lower level to a higher level. A continuous stream of air at a high velocity lifts the capsules up as the capsules are fed into the machine at a lower level and conveys them to a higher level. The air flow required for lifting the capsules is developed with the help of a rotating impeller. The free air is sucked in and discharged at a higher velocity by the rotating impeller, in the bottom pipe. The filled capsules are fed in the in-feed chute of the bottom pipe and get lifted up by the high velocity air stream to the top pipe and then to the delivery chute. The capacity of this equipment is 100,000 capsules/hour.

6) Metal Detector:

A metal detector is a peripheral equipment that can be attached to a capsule filling machine to detect any metal contaminants that may be present in the capsules. The capacity of this equipment ranges from 100,000 to 200,000 capsules/hour

7) Check Weigher:

In the Auto mode of operations, the sampling flap will automatically open after a certain duration. The vibrator pan starts vibrating and the capsule falls on to the weighing pan. While falling on to the weighing pan, an infrared (IR) sensor senses the entry of the capsule and the pan stops vibrating. The capsule weight is read by the Programmable Logic Control (PLC) and an air jet ejects capsules from the weighing pan to a collection box. Then the vibrator pan starts vibrating and the cycle is repeated. After completion of the weighing of the samples, the printer starts printing data and the purging operation takes place automatically to remove capsules in the hopper. It generates a report of 20 capsules at a time.

8) Capsule De-Duster (ADU):

The machine consists of an Impeller enclosed in an Impeller Housing with a suction and exhaust port. As the impeller rotates at a high speed, a partial vacuum is created in the impeller Housing. Atmospheric air is sucked in from the suction port and exhausted from the exhaust port. The capsule de-duster is basically a vacuum cleaner, the suction side of which is used for sucking the dusted powder from the capsule polishing machines. The CFM capacity of the de-duster ranges from 100 to 300.

9) Empty Capsule Sorter (ES):

An empty capsule sorter is a peripheral equipment that consists of sorting plate through which the capsules are passed. There’s continuous flow of air stream through the centre of the sorting plate. In case a capsule is empty, it won’t pass through the sorting plate and keep floating on, and will eventually be removed manually.

The innovative designs of peripheral equipment at F Plus Healthcare, with its impressive features, comes as a reliable solution to pharmaceutical companies, both large-scale and small, across countries like Bangladesh, Algeria, Iran, Sir Lanka, Iraq, Vietnam, Thailand, KSA, Philippines, and Russia among others. You can find out a lot more about the range of equipment at F Plus Healthcare and take a look at our portfolio to equip your company with the right machinery.

Contact us at [email protected] or on WhatsApp at +91 75062 17809.