The Need for Capsule Filling Machines in the Pharma Industry

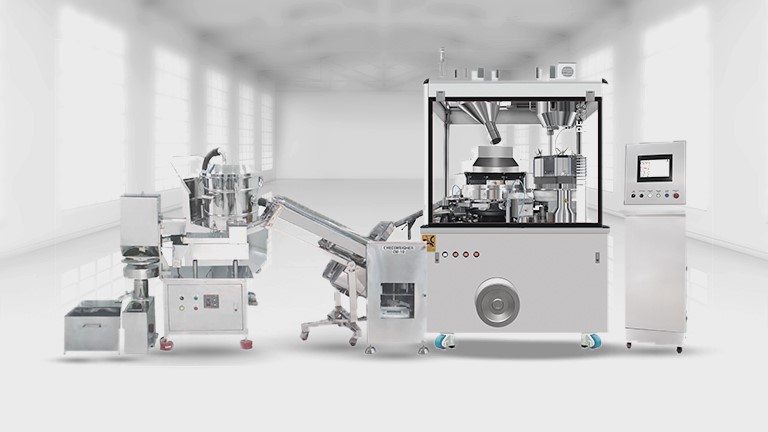

Capsule filling machines automate the process of filling the desired amount of medication in empty capsules, which is then sealed to form a complete capsule. The machine consists of a hopper to hold the medication, a dosing disc to measure the correct amount of medication, and a mechanism that fills the capsules. Automatic capsule filling machines are designed to handle a wide variety of capsule sizes and types, including gelatine and vegetarian capsules. In addition to their speed and accuracy, automatic capsule filling machines also offer other benefits such as reduced waste, increased efficiency, and improved quality control.

While purchasing a capsule filling machine, you can choose from a range of options that differ in their working processes, applications, and designs. These include –

-

- Fully automatic capsule filling machines: These are machines designed to automatically fill capsules, ensuring a large production. Fully automatic capsule filling machines are more productive and convenient than their semi-automatic or manual counterparts.

- Semi-automatic capsule filling machines: Semi-automatic capsule filling machines involve both automatic processing and human intervention. These are convenient in their design and operations.

- Manual capsule filling machines: Manual capsule filling machines are majorly used in R&D Labs and small-scale pharma industries that produce smaller quantities of capsules. These machines are operated manually and need no power.

The Types of Capsule Filling Machines

Pharma companies make use of two major types of capsule filling machines known for their different filling principle – the dosator capsule filling machine and the tamping pin capsule filling machine.

The Dosater-Type Capsule Filling Machine

A dosator capsule filler functions by dispensing the accurate amount of medication in the capsules with the help of a dosing disc. The capsules are separated into individual units before moving to the dosing station. The medication is then dispensed and the excess scraped off using a knife. The filled capsules are then moved to the closing station where they are sealed.

The Tamping-Type Capsule Filling Machine

Unlike the dosater-type machine, the tamping-type machine uses a tamping pin to compress the medication into the capsule. The capsules, once separated into individual units, are then moved to the filling station where medication is dispensed into the unit. A tamping pin then compresses the medication to fit it within the capsule. Once compressed, the excess is scraped off and the filled capsule units move on to the closing station to be sealed.

Factors to Consider when Choosing an Automatic Capsule Filling Machine

When choosing an automatic capsule filling machine, here’s what to consider:

The type of capsule being filled: A fully automatic capsule filling machine can fill capsules ranging from size ‘000’ to ‘5’.

The inner-material component: Capsule filling machines come equipped with different attachments that can handle multiple components of materials, whether powder, granules, pellets, liquids, gel, tablet, capsule, or micro-tablet.

The type of machine being used: The type of machine is determined based on one’s requirements, which includes the output, the sizes of the capsules, the material components, etc.

The Benefits of Choosing Tamping-Type over Dosater-Type Capsule Filling Machines

-

- In recent times, the capsule filler manufacturers have made advancement in their technology by assuring a guaranteed fill volume of up to 15mg which has been a significant improvement and breaks the myth that tamping type isn’t capable of micro dosing.

- The tamping pin technology is used for a wide range of production needs such as filling bad fluid powder, food products, medicines, nutraceuticals etc.

- From the operation & maintenance point of view, this machine is extremely reliable and cost effective.

- It has adjustable settings that allow you to configure the filling levels of the capsules.

- Most parts of the machine have tight enclosures, preventing the entry of dust and other foreign materials

- The machine can be integrated with other machines thus forming a complete production line.

- Initial cost of investment is low as compared to dosator type and in terms of efficiency and output tamping type outperforms it.

- With the help of multiple replaceable parts, the cost of maintenance can be reduced drastically.

Find the Right Capsule Filling Machine with F Plus Healthcare

At F Plus Healthcare, we manufacture & supply various capsule filling machine R&D, Pilot scale & production scale model & its peripheral equipment to our customers located across the globe like Thailand, Vietnam, Russia, Philippines, Turkey, KSA, Iran, Iraq, Palestine, Syria, UAE, Algeria and many more.

Our representatives can take you through our portfolio of capsule fillers for a detailed understanding of their workings and benefits. To learn more, [email protected] or on WhatsApp at +91 75062 17809.