Capsule Filling Machines

Encapsulation is the filling of capsule with the desired drug. It is done using tamping principles. The powder formulation is formed into a slug which is delivered to the body of the capsule. The process ensures encapsulating hard two piece capsules with precise dose, gives better weight control and with improved yield. Automatic capsule-filling machines are designed to cater to a wide range of formulations with powder / granules, pellets / sustained release spherical pellets, tablets, filled capsules and combination of these. Automatic capsule-filling machines are capable of encapsulating wide range of capsules from size 000 to size 5 hard two piece capsules with a varied output range of 25000, 40000, 90000 and 150000 capsules per hour.

We offer

Automatic Capsule Filler - PF90

F+ automatic capsule filling machine, PF90 has been designed to fill hard two pieces capsules with a variety of powders, pellets and tablets. The machine is operator friendly, compact in design and runs on the tamping principle. The machine can fill capsules from size”000” to “5”.

Automatic Capsule Filler - PF150

PF150, maximize output with minimum product loss.

The PF150 offers one of the fastest capsule filling speeds, of up to 150,000 capsules per hour for powder, pallets and tablets. It offers feasibility of Micro-dosing up to 15 mg with an accuracy of ± 2mg depending up on the formulation characteristics and flow properties.

Automatic Capsule Filler - PF40

PF40, maximize output with minimum product loss.

The PF40 offers speeds of up to 40,000 capsules per hour for powder, pellets and tablets. It offers feasibility of Micro-dosing up to 15 mg with an accuracy of ± 2mg depending up on the formulation characteristics and flow properties.

Automatic Capsule Filler - PF25

PF25, compact machine for small to medium size batches.

The PF25 offers speeds, of up to 25,000 capsules per hour for powder, pellets and tablets. It offers feasibility of Micro-dosing up to 15 mg with an accuracy of ± 2mg depending up on the formulation characteristics and flow properties.

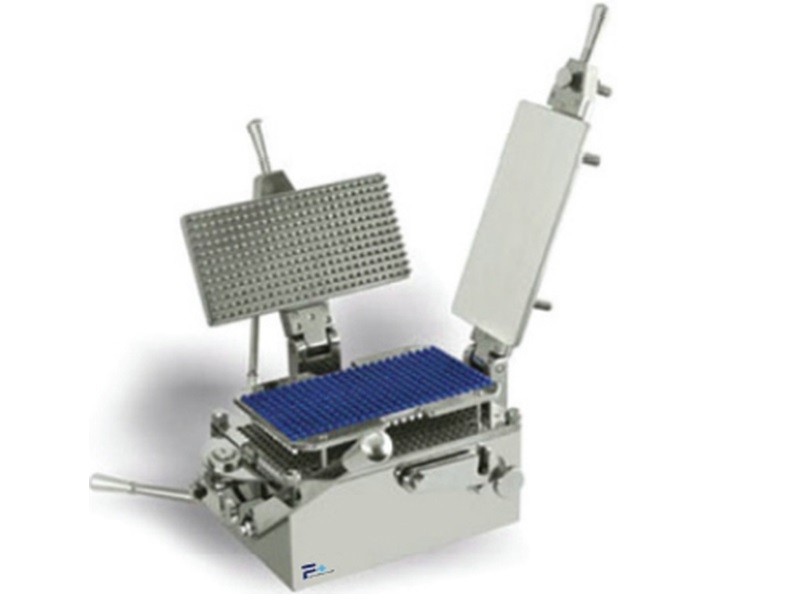

Minicaps

Minicaps has been designed an automated benchtop capsule filling machine to fill hard two piece capsules with a variety of powders, pellets and tablets. The machine can fill capsules from size”000” to “5”. The machine is designed as per GMP, GAMP and CE norms.

Semi-Automatic Capsule Filling Machine - Double Loader - DL10

Features:

• Automatic loading and filling minimizes operator attention.

• Double loading station to ensure highest output.

• Machine is operated through PLC with display of various parameters.

• Special hopper design is easy for dismantling and cleaning.

• Easy changeover of change parts (maximum 15 minutes required to change).

• Complying to cGMP standards.

• Automatic closing and ejection of filled capsules to ensures operator’s safety.

Semi-Automatic Capsule Filling Machine - Single Loader - SL10

Features:

• Automatic loading and filling minimises operator attention.

• Single loading station to ensure higher output.

• Machine is operated through PLC with display of various parameters.

• Special hopper design is easy for dismantling and cleaning.

• Easy changeover of change parts (maximum 15 minutes required to change).

• Complying to cGMP standards.

• Automatic closing and ejection of filled capsules to ensures operator’s safety.

Manual Capsule Filling Machine - HF 30

Features:

• Maximum output 55,000 – 60,000 capsules per 8 hour shift.

• Ideal for R&D sect ion, small / medium scale pharmaceutical units.

• Simple operation, giving precise result with less rejection.

• Sturdy, easily movable.

• Interchangeable parts can be supplied for all standard size capsules from 00 to 5.d capsules to ensures operator’s safety.

Capsule Polisher - DPM 100

Features:

• The polishing chamber inclination are adjustable to suit the formulation.

• Provision of compressed air for cleaning the nylon brush.

• The polishing chamber is to be connected to a vacuum cleaner to suck the de-dusted powder from the polishing chamber.

• No change parts are required for different size of capsules.

• Easy to dismantle, wash and reassemble.

• Very little maintenance is required for this machine except for periodic cleaning.

• Mounted on a stand with locking type wheels and can be freely moved about and taken to any place for putting it in operation.

Sample Checkweigher - CW 20

CW 20 is a fully-automatic online sample checkweigher designed for statistical weight control to check samples of filled capsules. With an accurate weighing balance of up to 1 mg, the Sample Checkweigher guarantees against weight variations and ensures reliable results.

Capsule Sorter Elevator - ECSE 100

Empty capsule sorter elevator is designed to transfer empty capsule to the machine capsule hopper.

Features:

• Small machine, occupying very little space.

• Sorts out diametrically defective capsules.

• Output of up to 120,000 capsules per hour, depending on the capsule-filling machine.

Filled Capsule Sorter - FCS 100

Features:

• Simple, less maintenance and GMP compliant.

• Eliminate empty capsule, loose cap and body to ensure only filled capsules are in the output.

• No change parts are required for different capsule size.

• All components coming in contact with the capsules are made of stainless steel or other approved materials.

• Small footprint and easy movable.

Mini Capsule Sorter MCS 100

MCS 100 is specially designed for automatic sorting of loose caps, loose bodies and diametrically defective filled capsules.

Features:

• Removes diametrically distorted capsules, loose caps, body and loose powder.

• Compact in Size, taking up very little space.

• All contact parts made of SS-316 and all aluminium parts are specially plated.

• Sorts capsules of sizes 000 to 5.

Capsule De-Duster - ADU 100

A dust extraction unit, which is used for collecting loose powder from the polishing chamber. It is also used for cleaning operations on automatic capsule-filling machines.

Features:

• Quick clamping arrangement for vaccum chamber lid.

• Large surface area for filteration due to pleated filter bag.

• Provision of shaker to remove powder from the filter bag.

Metal detector

The Metal Detector are used for online inspection of capsules and separate metal contaminated product from them without production interruption from a stream of capsules and tablets.

Features:

• Automatic balance.

• Modular plug in card system.

• Product effect cancellation control.

• Adjustable sensitivity.

• Detect all types of metal.

• All contact parts are manufactured with approved material.

• Height and position adjustable system.

Empty Sorter ES 100

Empty sorter is designed to sort empty capsules and semi filled capsules from the final filled capsules.

Features:

• Sorting of filled capsules and empty capsules.

• All contact parts ss 304 .

• Integrated with speed controller blower.

• Can be sorted for capsule size “000” to size “5”.

• Small and accurate.

Automatic Capsule Loader - Vertical / Horizontal - CL 90

Features:

• Ideal for small / medium scale pharmaceutical units which can make a significant difference in your production unit.

• This machine is compact, occupies minimal space, easy handling and user friendly.

• More accuracy with economic production cost.

• The base & covering of the machine is fabricated from stainless steel with duly polished.

• Designed to fill all standard capsule sizes from 00 to 5.

Encapsulation is the process of filling a pill with the desired drug or medicine. It is completed using tamping ideas with the help of a capsule filling machine. The powder formulation of the drug or medicine is fashioned right into a slug that is then introduced to the body of the tablet. The technique of the best capsule filling machine guarantees that encapsulating even the hard piece capsules with the precise dose, gives a better weight control and with an improved yield can be done.

There are two major types of capsule filling machines – Automatic capsule filling machines and semi-automatic capsule filling machines. There is also a third type of capsule filling machine – manual capsule filling machine.

As automatic capsule filling machines manufacturers, we design them to cater to a huge range of formulations with powder/granules, pellets/sustained launch round pellets, capsules, filled capsules and a mixture of these. An automatic capsule filling machine is mostly used by pharmaceutical companies to help with the production of hard gelatin capsules. The presence of tamping pin technology in the automatic capsule filling machine helps in the slug formation that accurately pushes the hard gelatin capsule. Automatic capsule filling machines are also able to encapsulate many varied kinds of tablets from size 000 to size five hard 2-piece capsules with a varied output range of 25000, 40000, 90000 and 150000 tablets in line with hour. On the other hand, the semi auto capsule filling machines are, as the name suggests, are not automatic and need human intervention from time to time. The output of semi automatic solutions depends on the ability of the operator and also the size of the tablets being produced. As semi automatic capsule filling machine manufacturers, we ensure that the semi auto capsule filling machine can make up to 25000 capsules an hour. We are also manual capsule machine manufacturers and have a bunch of options available on our website.

Browse our website to know more about these machines and reach out to us in case you have any queries or would like to do business with us.

Are you in a new industry that has ventured into the world of pharmaceuticals but cannot find the perfect technology to aid you in the process? It is because of this reason that we are here at F Plus Healthcare Technologies LLP; we have got the best capsule filling machine for you! We aim to make capsule filling easy for you, and with the expertise of the machine, you will be able to fill out a lot of capsules in one go!

As the best automatic capsule filling machine manufacturer in India, we make sure that we pay the ultimate focus on none other than efficiency. The most amazing features of the capsule filling machine include the following:

1. Ease of usage

2. Affordable price range

3. After-sales support

4. Great capacity to fill out capsules

If you think that you want the best option for the capsule filling machine, the only option you ever need is to join hands with the top tablet coating machine manufacturers in India. Trust is us at F Plus Healthcare Technologies LLP. You can trust when it comes with good quality machines for a sustainable investment!