Choosing the Right Capsule Filling Machine: A Complete Guide for R&D, Pilot, and Production Scale

At F Plus Healthcare Technologies the capsule filling machine is available in different models, including R&D, pilot scale, and production scale models, & their peripheral equipment to our customers located across the globe catering to the specific needs of its intended use. The R&D model is ideal for research and development purposes, while the pilot scale model is suitable for small-scale production, such as clinical trials. The production scale model is capable of high-capacity production and is perfect for large-scale pharmaceutical manufacturing. The tamping principle is a widely used filling technique that offers accurate dosing, easy maintenance, low cost, and minimal training for operators.

1) Fully automatic capsule filling machines:

These are machines designed to automatically fill capsules, ensuring a large production. Fully automatic capsule filling machines are more productive and convenient than their semi-automatic or manual counterparts.

2) Semi-automatic capsule filling machines:

Semi-automatic capsule filling machines involve both automatic processing and human intervention. These are convenient in their design and operations.

Semi-automatic capsule filling machines involve both automatic processing and human intervention. These are convenient in their design and operations.

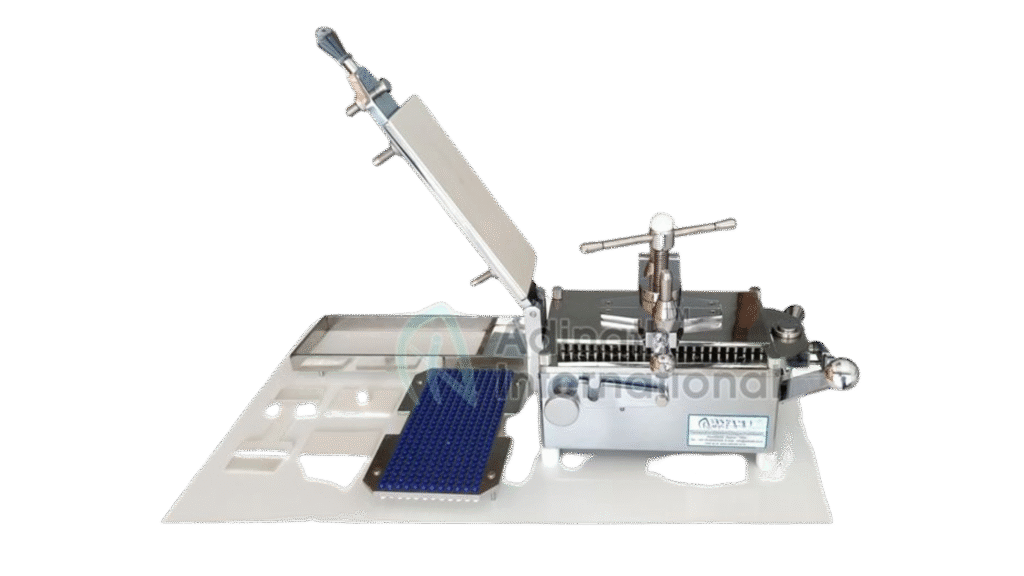

3) Manual capsule filling machines:

Manual capsule filling machines are majorly used in R&D Labs and small-scale pharma industries that produce smaller quantities of capsules. These machines are operated manually and need no power.

The output capacity of F Plus Healthcare Technologies’ Automatic Capsule Filling Machine ranges from 3,000** to 200,000** capsules per hour, making it suitable for both small and large-scale productions. The machine is equipped with multiple attachments that can handle different types of products, including powder, granules, pellets, tablets in capsule, capsule in capsule, liquid in capsule, and micro-tablets in capsule. (** the output capacity will depend on bulk density, flowability, compressibility of the product)

Dosator vs. Tamping Pin: Two key capsule filling machines pharma relies on.

-

The Dosater-Type Capsule Filling Machine

A dosator capsule filler functions by dispensing the accurate amount of medication in the capsules with the help of a dosing disc. The capsules are separated into individual units before moving to the dosing station. The medication is then dispensed and the excess scraped off using a knife. The filled capsules are then moved to the closing station where they are sealed.

-

The Tamping-Type Capsule Filling Machine

Unlike the dosater-type machine, the tamping-type machine uses a tamping pin to compress the medication into the capsule. The capsules, once separated into individual units, are then moved to the filling station where medication is dispensed into the unit. A tamping pin then compresses the medication to fit it within the capsule. Once compressed, the excess is scraped off and the filled capsule units move on to the closing station to be sealed.

The Benefits of Choosing Tamping-Type over Dosater-Type Capsule Filling Machines

➕In recent times, the capsule filler manufacturers have made advancement in their technology by assuring a guaranteed fill volume of up to 15mg which has been a significant improvement and breaks the myth that tamping type isn’t capable of micro dosing.

➕The tamping pin technology is used for a wide range of production needs such as filling bad fluid powder, food products, medicines, nutraceuticals etc.

➕From the operation & maintenance point of view, this machine is extremely reliable and cost effective.

➕It has adjustable settings that allow you to configure the filling levels of the capsules.

➕Most parts of the machine have tight enclosures, preventing the entry of dust and other foreign materials

➕The machine can be integrated with other machines thus forming a complete production line.

➕Initial cost of investment is low as compared to dosator type and in terms of efficiency and output tamping type outperforms it.

➕With the help of multiple replaceable parts, the cost of maintenance can be reduced drastically.

Choosing the Right Capsule Filler? Here’s What You Need to Know

The type of capsule being filled: A fully automatic capsule filling machine can fill capsules ranging from size ‘000’ to ‘5’.

The inner-material component: Capsule filling machines come equipped with different attachments that can handle multiple components of materials, whether powder, granules, pellets, liquids, gel, tablet, capsule, or micro-tablet.

The type of machine being used: The type of machine is determined based on one’s requirements, which includes the output, the sizes of the capsules, the material components, etc.

One of the significant advantages of F Plus Healthcare Technologies’ Automatic Capsule Filling Machine is its versatility. The machine is compatible with two types of capsules – gelatin and HPMC (hydroxypropyl methylcellulose). Both gelatin and HPMC capsules come in different sizes, ranging from 000 to 5, all of which the pharmaceutical capsule filling machine is well able to handle. The machine’s ability to handle different capsule types and sizes allows manufacturers to produce a wide range of pharmaceutical products suitable for different dietary needs and preferences.

F Plus Healthcare Technologies’ Automatic Capsule Filling Machine is designed for easy maintenance and repair, consist of modular parts, readily-available spares and replacement parts. Operators need minimal training to operate and troubleshoot the machine internally, reducing downtime and increasing production efficiency. The machine is CE and cGMP certified, ensuring compliance with international quality and safety standards.

The machine’s accuracy is another significant advantage, with an accuracy of +-1%, ensuring that the capsules have the correct dosage and weight. Micro dosing upto 15mg is also possible. The machine’s efficiency, versatility, and easy maintenance have made it the preferred choice for many pharmaceutical manufacturers worldwide.

At F Plus Healthcare Technologies, we manufacture & supply various capsule filling machine R&D, Pilot scale & production scale models, & their peripheral equipment to our customers located across the globe. To learn more, you can contact us at [email protected] or on WhatsApp at +91 75062 17809.